Spain (Valencia)

The combination of laser and ozone technologies allows Jeanologia to finish a pair of jeans using just a glass of water, rather than the industry average of 70 litres.

The world’s resources cannot keep up with the increasing demand for our throwaway fashion culture. Cotton production is responsible for 2.6% of global water use. If we do nothing to correct this imbalance, by 2030 demand for water will exceed supply by 40%.

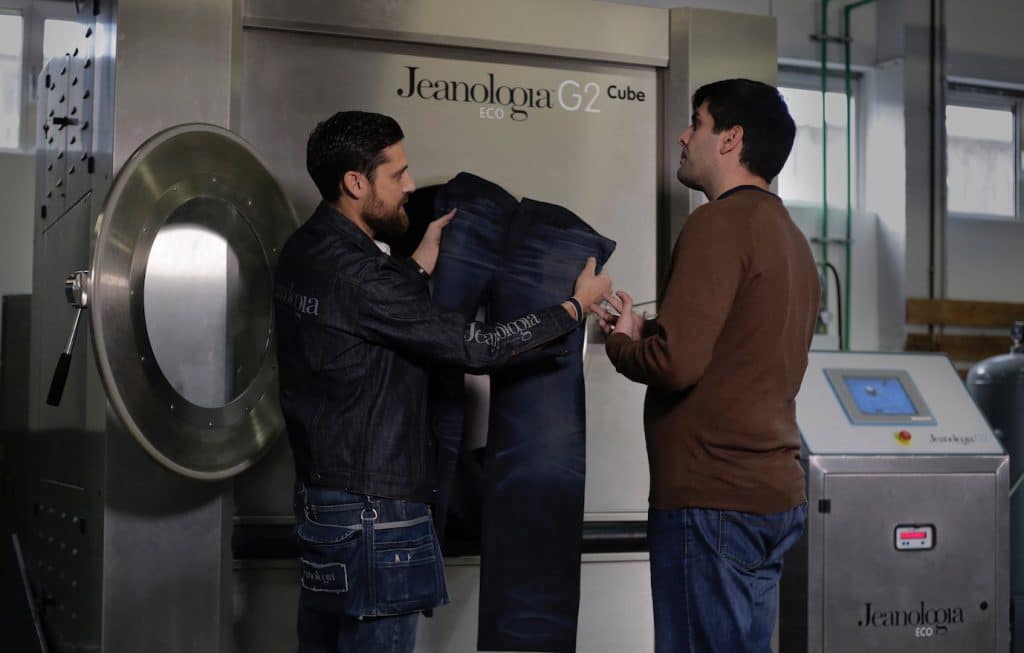

Denim jeans are an iconic garment, but are one of fashion’s most water-heavy, toxic and energy-consuming fabrics. Spanish-based software company Jeanologia has developed sustainable production methods for garment finishing that cut as much as 90% of water from the process. The combination of laser and ozone technologies allows them to impress patterns and finish a pair of jeans with only a glass of water.

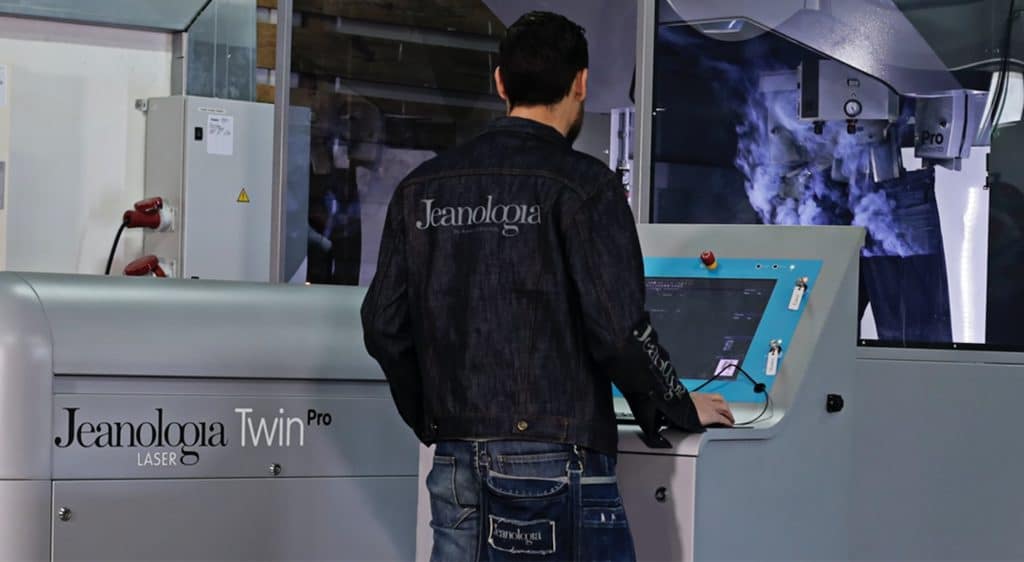

The technology allows the design of the jeans to be sketched out on a computer and drawn directly onto the fabric using a laser, without adding toxic chemicals.

Afterwards, there’s a process called ‘ozone washing’, which naturally ages the denim in an eco-friendly, non-polluting way. The result is a huge water saving.

Jeanologia helps some of the world’s biggest clothing brands reduce their environmental impact – enhancing productivity, reducing water and energy consumption and eliminating damaging emissions and waste. Over 35% of the 5 billion jeans produced worldwide every year are made with Jeanologia eco-efficient technologies. And that’s a lot.

“When we started, we used to tell our clients that saving the planet could be a great business and they thought we were Greenpeace.” – Enrique Silla, founder

The machines designed and built by Jeanologia are used by some of the world’s largest denim makers in Bangladesh, Pakistan, Turkey and Vietnam that supply a large share of the textiles used by big brands. And this technology doesn’t just help save water. Manufacturers are also cutting energy consumption, their biggest source of carbon emissions.

Jeanologia is also helping the textile sector with the first software in the world to measure environmental impact in the clothing industry. It’s appropriately named Environmental Impact Measuring (EIM).

This user-friendly tool calculates the impact of production based on consumption of water, energy, chemicals and the health of the workers. This enables the manufacturer to clearly see the major causes of environmental hazards and create clarity for the consumer. The app helps global producers and brands optimise washing processes, making them more sustainable, while lowering production costs.

When creating Conscious Denim in October 2014, H&M used criteria from Jeanologia to test its denim washing processes, including water and energy consumption. Now, this technology has been used by some of the world’s most well-known fashion labels, including Levi Strauss, Tommy Hilfiger and Calvin Klein.

Watch this video to see how Levi Strauss has implemented Jeanologia technology:

From Valencia, Jeanologia coordinates the work of over 220 workers throughout the world. They develop and manufacture their laser technology in Barcelona and have an ozone technology production center in Turkey. To date, they have installed over 2,500 machines around the world.

Jeanologia has also created The School, a training programme for the new generation of laser designers, giving them the chance to acquire all the knowledge and abilities they need to design and produce jeans sustainably.

AtlasAction: Follow Jeanologia on Twitter or Instagram for updates.

Project leader

Enrique Silla, founder, Jeanologia

Support the Atlas

We want the Atlas of the Future media platform and our event to be available to everybody, everywhere for free – always. Fancy helping us spread stories of hope and optimism to create a better tomorrow? For those able, we'd be grateful for any donation.

- Please support the Atlas here

- Thank you!